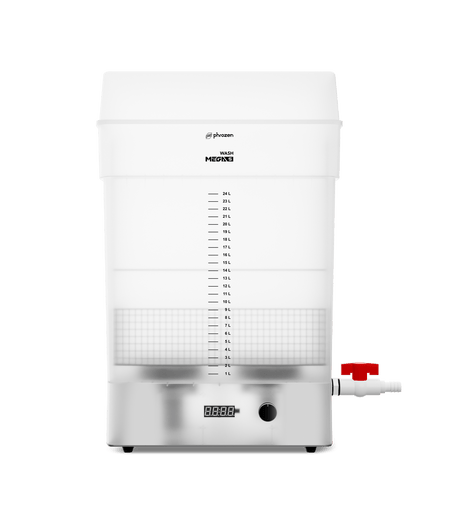

Wash & Cure Stations

(7 products)

Take your resin 3D printing workflow to the next level with our range of Wash & Cure Stations designed to make post-processing faster, cleaner, and stress-free. Washing and curing are essential steps for achieving strong, accurate, and professional-quality prints. With premium build quality and powerful UV curing systems, these stations are built to handle everything from small miniatures to large-format models.

Why Use a Wash & Cure Station?

-

Cleaner Prints – Effectively remove uncured resin for a flawless surface finish.

-

Stronger Results – Proper curing ensures maximum strength and durability.

-

Time Saving – Streamline your workflow with easy one-touch operation.

-

Professional Finish – Achieve consistent results for hobby, dental, jewellery, and industrial applications.

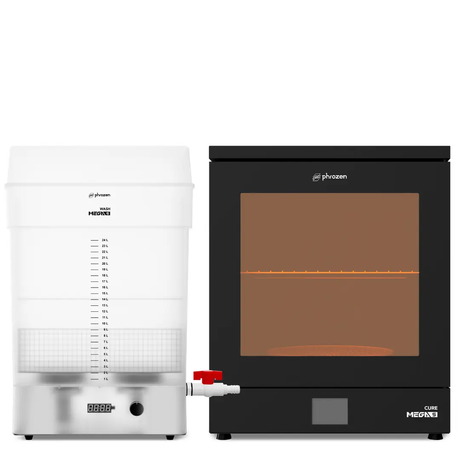

Bundle Deals – Save More

Looking to set up a complete post-processing system? Our bundles offer excellent value while giving you everything you need in one package

Whether you’re printing tabletop miniatures, dental models, or industrial prototypes, our Wash & Cure stations and bundles will ensure every project comes out clean, strong, and professional. All products are stocked locally in Australia and shipped fast by 3D Cast.

What are Wash & Cure Stations?

Wash & Cure Stations are specialized devices used in the post-processing of 3D printed parts. They help clean the prints to remove excess resin and then cure the prints to ensure they are solid and durable. These stations are essential because they improve the quality of the final product. Unlike traditional methods, these stations automate the cleaning and curing process, which saves time and reduces the mess associated with handling resin.

Benefits of Using Wash & Cure Stations

One major benefit of Wash & Cure Stations is that they increase efficiency. By streamlining the cleaning and curing steps, users can focus more on design and production. Additionally, because these stations are designed specifically for resin parts, they often lead to better surface finishes, which enhances the aesthetic and functional quality of the print. Therefore, many 3D printing businesses invest in these stations to enhance their workflow and improve product quality.

Choosing the Right Wash & Cure Station

When selecting a Wash & Cure Station, it’s important to consider factors such as size, compatibility with different resin types, and the capacity to handle your specific 3D printing needs. Some stations come with additional features like built-in timers or temperature controls, which can optimize the curing process. Because there are many options available, consumers should evaluate their requirements to find the best station that meets their needs.