How to 3D Print a Dental Model for Thermoformed Clear Aligners

A Beginner Digital Manufacturing Guide for Dental Laboratories & Clinics

Purpose of This Guide

This guide is designed for dental laboratories & Clinics looking to begin or expand into in-house dental 3D printing.

Modern dental labs are rapidly transitioning from traditional fabrication toward controlled digital manufacturing workflows. 3D printing allows laboratories to produce appliances faster, reduce remakes, standardise quality, and scale production without increasing technician labour time. However, successful dental printing does not come from simply owning a printer, it comes from understanding and controlling the repeatable workflow used by digital laboratories.

Many labs attempting 3D printing for the first time struggle not with the technology itself, but with process control. Small variations in scan preparation, model design, print orientation, washing, or curing can lead to distortion, inaccurate appliances, and lost confidence in the technology. The goal of this guide is to provide a clear starting workflow that mirrors the structured production approach used in established digital labs.

Rather than covering every dental application at once, this document uses a single reliable entry point into dental 3D printing:

The production of dental models used for thermoformed clear aligners.

Aligner models are ideal as a first application becausethey:

• Follow a repeatable workflow

• Represent true production use

• Quickly reveal whether the workflow is controlled

By learning this workflow, a laboratory builds the foundation required for surgical guides, splints, retainers, trays, dentures and other printed appliances. The objective is not just to print a model, but to establish a predictable digital manufacturing process that can be applied across all future indications.

Workflow Overview

- Receive or capture the scan

- Prepare the model in dental CAD software

- Prepare the print in slicer software

- Print the model

- Wash and cure

- Quality control

- Thermoform appliance

Step 1

Receiving or Capturing the Scan

Goal: obtain an accurate digital impression (STL file)

Scans may come from:

• Intraoral scanners (Trios, Medit, iTero, Primescan etc)

• Desktop lab scanners

What to check before working on the file

Inspect the scan carefully:

• Full molars captured

• Gingival margins visible

• No holes in occlusal surfaces

• Contacts readable

• No major artifacts or floating geometry

• Bite scan aligned correctly

If the scan is poor, printing will not fix it. Always verifybefore designing.

File format

Export or request: STL (preferred)

Name files consistently:

PatientName_Date_Upper.stl

Step 2

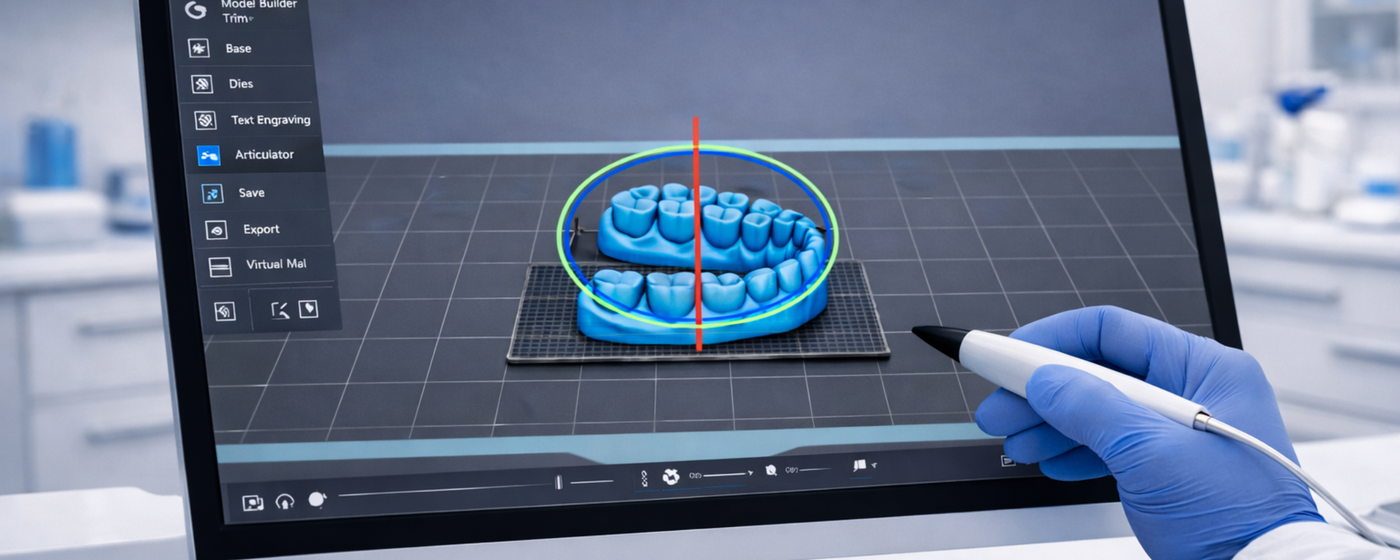

Model Preparation (Dental CAD Software)

Prepare a printable working model, not just the raw scan.

Common dental CAD software:

• 3Shape Dental System / Ortho Analyzer

• exocad Model Creator / Ortho Module

• Medit Model Builder

• BlueSkyPlan

Clean the scan

Remove:

• Scan artifacts

• Floating triangles

• Excess soft tissue

• Fill small holes if needed

Create the model base

Recommended settings:

• Base height: 5–10 mm

• Flat base for thermoforming

• Vertical walls

• Do not hollow the model

A stable base prevents thermoforming distortion.

Block out undercuts

Undercuts can lock plastic onto the model. Use automatic block-out or orthodontic smoothing tools in

your CAD software.

Trim gingiva

Trim approximately 2–4 mm below gingival margin.

Too high = plastic tearing

Too low = poor retention

Add identifiers

Always label the model:

• Patient initials

• Stage number

• Upper or lower arch

Prevents production mix-ups.

Export

Export the finished model as an STL ready for printing.

Step 3

Prepare the Print (Slicer Software)

Open the STL in the printer slicer software.

Examples:

• Phrozen DS Slicer

• Chitubox Dental

• Lychee (dental profiles)

Orientation

For aligner models:

Best accuracy = flat on build platform (0 degrees)

This reduces distortion and improves appliance fit.

Supports

Minimal or no supports on tooth anatomy.

Never place supports on:

• Cusps

• Incisal edges

• Contact points

Layer height

Typical settings:

100–160 µm = production speed

50 µm = high accuracy cases

Resin selection

Selecting the correct resin is just as important as choosing the printer. For clear aligner model production, the goal is not biocompatibility the model never enters the mouth, but dimensional stability and resistance to thermoforming heat.

A good aligner model resin should:

• Hold fine detail and margins

• Resist softening during vacuum forming

• Maintain dimensional accuracy after curing

• Produce a smooth surface so aligners stay clear

• Be easy to clean and repeatable to process

Different clinics prioritise different factors such as cost, speed, surface finish or convenience. Because of this, multiple resin types are commonly used in practice.

General Purpose Model Resin (Most Common Starting Point)

Most clinics begin with high-detail model resins. These provide an excellent balance of accuracy, surface quality and reliability and are suitable for everyday aligner workflows.

We typically recommend using Phrozen 4K or 8K model resins as the primary choice because they:

• Produce smooth thermoforming surfaces

• Hold margins consistently

• Have predictable curing behaviour

• Work across a wide range of printers

These are the most widely adopted resins for starting chairside aligner production.

Easy Handling Option (Simplified Cleaning)

Some clinics prefer simpler post-processing rather than maximum surface detail. In this case water washable resins are commonly used.

Phrozen Water Washable Model Gray is often chosen when:

• Staff are new to printing

• A dedicated wash station is not yet installed

• Simpler cleaning workflow is preferred

This can make onboarding much easier for clinics running their first in-house cases.

Heat Resistant Models (Thermoforming Stability)

If aligners are formed using higher pressure or temperature, stronger engineering resins can improve model longevity and reduce deformation.

Resins such as Phrozen TR250LV and Phrozen TR300 are commonly selected when:

• Using pressure forming machines

• Producing multiple aligners from one model

• Models experience distortion during forming

• Higher repeatability is required

These trade a small amount of print speed for improved thermal resistance.

Dedicated Dental Workflow Option

Some clinics prefer materials specifically designed for dental workflows.

Phrozen Dental Water Washable resin is used when:

• A dental-specific workflow is preferred

• Simplified cleaning is required

• Standardised processing procedures are desired

This provides a balance between convenience and predictability.

Which Should You Start With?

For most clinics starting chairside aligner production:

1. Start with a high detail model resin

2. Move to engineering resin if deformation occurs

3. Adopt dental workflow materials as production increases

The most important factor is consistency.

Once a resin is chosen, keep the same exposure settings, wash time and cure cycle so results remain predictable.

Step 4

3D Printing

- Shake resin bottle

- Fillvat

- Startprint

- Confirm first layers adhere

Typical print time: 20–60 minutes

Step 5

Washing and Post Processing

This stage strongly affects final accuracy.

Wash

Recommended two stage wash:

First wash remove bulk resin, using a bucket is a great way of removing the excess resin.

Second wash clean rinse in a purpose built wash station will ensure great cleaning results.

Total time: 3–6 minutes

Dry

Air dry in a dark cool place or use compressed air to speed up the process.

Please ensure all models are dry before before curing.

Remove supports

Carefully cut supports, lightly smooth contact points if required and avoid damaging tooth anatomy.

Cure

Cure using a dental curing unit following resin instructions. Correct curing provides heat resistance required for thermoforming.

Step 6

Quality Control

Inspect model carefully:

• No warping

• Contacts clear

• Surfaces matte not glossy

• Gingiva trimmed correctly

• No uncured resin

If the model passes inspection, it is ready for forming.

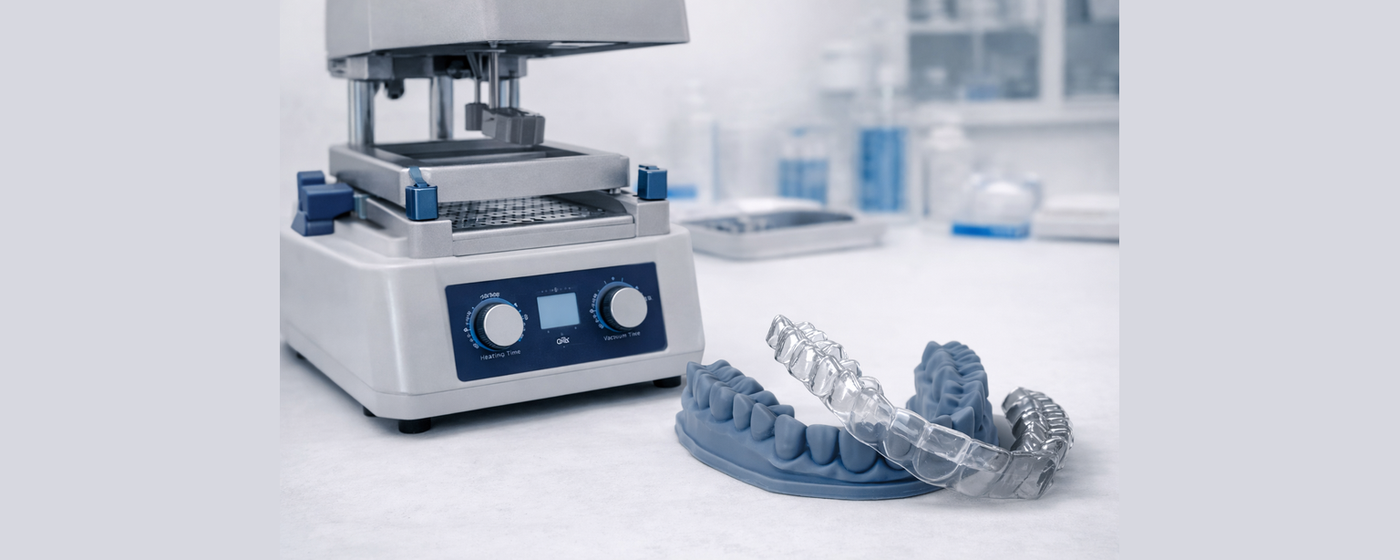

Step 7

Thermoforming the Clear Aligner

Once the printed model has been washed, fully cured and inspected, it is ready for appliance production. At this stage the digital workflow returns to a familiar dental process, thermoforming.

A thermo vacuum or pressure moulding machine is used to form the aligner material over the printed model.

Preparation

Before forming:

• Ensure the model is completely dry

• Confirm no uncured resin remains (surface should be matte)

• Remove any sharp support marks that may tear the plastic

• Allow the model to cool after curing if recently processed

Incomplete curing or residual solvent can cause distortion during heating.

Forming the Aligner

- Place the model centrally on the forming platform

- Heat the aligner sheet according to manufacturer guidelines

- Lower the heated material over the model

- Activate vacuum or pressure forming

- Allow the material to cool fully before removal

Cooling is important removing the aligner early can cause warping.

After Forming

Once cooled:

• Remove the formed aligner from the model

• Rough trim excess material

• Finish and polish edges

• Check fit on the model before clinical use

Important Tip

The quality of the aligner is determined by the model.

If the model is accurate and stable, the appliance will fit predictably.

Most fit issues occur due to incomplete curing, overheating, or removing the aligner before cooling, not the printing itself.

Where to Go Next

Now that you understand the basic workflow, the next step is seeing how this process applies to a real clinical application.

A common starting point for clinics is producing accurate printed models used in appliance workflows. This helps your team build confidence with scanning, preparation, and post-processing before expanding into more advanced applications.

Choosing the Right Dental 3D Printing Equipment

Once the workflow is clear, equipment selection becomes much easier. Rather than focusing on specifications alone, you can choose hardware designed around predictable clinical workflows, validated materials, and repeatable results.

Clinics that successfully adopt 3D printing usually start small, establish a repeatable routine, and then expand into additional applications such as splints, guides, and in-house appliances.

Understanding the process first allows the technology to feel straightforward rather than experimental.

Continue Learning About Dental 3D Printing

Starting with the workflow gives your team confidence. From there you can explore individual parts of the process in more detail.

Understand the Equipment

Choosing the Right Printer

Join Our Dental Only Newsletter

Stay ahead in digital dentistry.

Our Dental Only Newsletter is designed exclusively for professionals in the dental industry, keeping you informed about new product launches, pre-orders, technical updates, and educational articles focused on real clinical applications.

We share only what matters to you, just valuable updates and insights to help your clinic or lab stay at the forefront of 3D printing technology.

👉 Join today to receive the latest Phrozen and Monocure3D dental product news, workflow tips, and educational content all tailored to Australian dental professionals.

To ensure we provide the best possible service for your clinic, please use the form below and select your enquiry type, whether it’s about product supply, account setup, or to join our newsletter.

We’ll review your needs and get back to you with tailored options for your clinic.

Contact form

3D Printing Dental Model for Thermoformed Clear Aligners Frequently Asked Questions

Do I need a dental lab to start making aligners in-house?

Do I need a dental lab to start making aligners in-house?

No. Modern intraoral scanners, dental CAD software and resin 3D printers allow clinics to produce aligner models chairside. Many clinics now manage scanning, model production and thermoforming themselves while outsourcing only treatment planning if desired.

Is dental 3D printing difficult to learn?

Is dental 3D printing difficult to learn?

Not really. The workflow is very repeatable:

Scan → Design → Print → Wash → Cure → Thermoform

Once your first few cases are completed, most clinics find the process becomes routine and predictable.

How accurate are 3D printed dental models?

How accurate are 3D printed dental models?

Dental resin printers routinely achieve accuracy within ±50 microns when using validated workflows.

This level of accuracy is suitable for:

• Clear aligners

• Retainers

• Study models

• Surgical guides (with approved materials)

Accuracy depends more on workflow consistency than printer price.

Do I need a specialised dental 3D printer?

Do I need a specialised dental 3D printer?

Dental-specific printers are designed for regulated materials and validated workflows and typically deliver the most predictable results.

However, many clinics successfully begin using high-resolution professional resin printers. While dental-grade printers deliver the best results, you can also produce accurate aligner models using printers such as the Phrozen Mighty 12K, Revo 14K or Revo 16K. When space is limited, compact printers like the Phrozen Mini 8KS are commonly used as an entry-level starting point.

How long does it take to print a model?

How long does it take to print a model?

Typical production times:

• Scan: 3–5 minutes

• Design: 5–10 minutes

• Printing: 30–60 minutes (multiple models at once)

• Wash & cure: 10–20 minutes

Most clinics produce same-day aligner models.

Can I print multiple aligner models at once?

Can I print multiple aligner models at once?

Yes. This is one of the biggest advantages of dental resin printing.

You can batch print a full aligner stage set in a single job overnight.

What resin should be used for aligner models?

What resin should be used for aligner models?

A rigid, high-detail model resin is recommended.

High resolution model resins are commonly used because they:

• Hold fine margins

• Resist thermoforming heat

• Maintain dimensional stability

• Provide smooth surfaces for clear aligners.

Speak to us for our recommendations to suit your needs.

Do printed models shrink or warp?

Do printed models shrink or warp?

Not when properly cured.

Warping typically comes from:

• Insufficient post curing

• Overheating during thermoforming

• Incorrect orientation

• Poor support placement

A validated curing workflow prevents this.

Do I need special software?

Do I need special software?

You should use dental CAD software rather than general 3D modelling software.

Dental CAD automates:

• Base creation

• Undercut blocking

• Trimming

• Model hollowing

• Articulation

This dramatically reduces learning time.

How often do printers need calibration?

How often do printers need calibration?

Very rarely. Modern resin printers are pre-calibrated.

Maintenance usually involves:

• Cleaning the vat

• Replacing film periodically

• Keeping optics clean